Forges

.

Audio Archive for the Tinkers Shop 11-09-13 (Right-Click to Download)

| Brake drum Forge | ||

|

Many people push the beginner to start with a brake drum forge. They would have the beginner believe that a 'brake drum' forge and a cheap hair dryer are a good substitute for a real blacksmiths bottom blast forge and blower. The work done with a brake drum forge is usually of the simplest design 'S' hooks, tent stakes and railroad spike knives. It is better to learn how the best forges work and to build something that functions much like the professional blacksmith's forge. A brake drum forge is only suited to the production of amall things because of the limitations that are inherent in it - the biggest limitation is the diameter versus the depth. For any projects of decent size you should have a coal depth of roughly 7." This is over half the width of most drums. Because of this you have the extreme hazard of coals falling out of the firepot and ending up underfoot! You also do not have any place to put your fire tools to keep them to hand. |

|

|

|

|

|

| My Portable Forge | ||

|

|

|

|

|

|

| Wood Box Forge | ||

|

This is what is sometimes called a 'Mud Box'

or Wooden forge. |

|

|

|

|

|

| Gas Forges | ||

|

Pictured to the right

are a group of smiths at a 'Demo' using a natural gas/LP gas forge. |

|

|

|

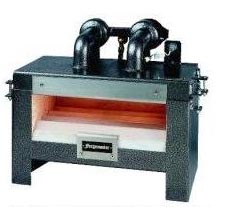

These are two smaller,

front loading, gas forges from Centaur Forge. |

|

|

| Coal Farriers Forge | ||

|

This is a modern update to the traditional

Farriers forge. |

|

|